Security Seals, Plastic Seals, Security Labels

IMPACT LABELS

A choice that makes the difference

Impact Labels | Shock Indicators

Shock Indicator, also known as impact indicator, can stick to your package or directly on a product inside for different needs in various industries. Activates from white to red to show impact when dropped. The red cannot be reset and provides shippers to pinpoint the irresponsible handling in your supply chain. A study shows the damage rate typically drops by 50% or more when a monitor is in place.

Product Feature:

![]() ALL IN ONE SYSTEM

ALL IN ONE SYSTEM

Warn, Detect, Indicate, Monitor, Track from Warehouse to Destination

![]() REDUCE LIABILITY & SAVE MONEY

REDUCE LIABILITY & SAVE MONEY

Reduces Transportation-Caused Damage, Liability, Cost, and Enhance Corporate Image

![]() LOGISTICS & HANDLING PROTECTION

LOGISTICS & HANDLING PROTECTION

Pinpoint Cargo Damage, Indisputable Evidence of Mishandling for Freight Claims, or Repeated Mishandling MECHANICAL OPERATION & SIMPLE TO USE No Electric Power Required, Only Peel and Stick

![]() TAMPER PROOF & ACCOUNTABILITY

TAMPER PROOF & ACCOUNTABILITY

Unique Serial Number to Verify Authenticity, Manage Product Conveniently, and Clarify Responsibility For Damage

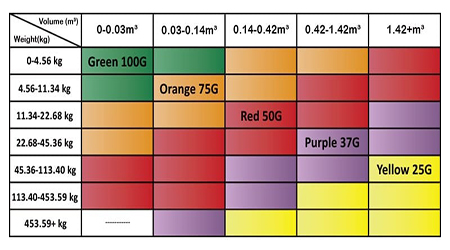

The shock indicator is a product that can indicate the shock force through the display window. Shock force is known as impact force or acceleration(G). The shock indicator can record the vibration intensity is recorded during transportation or goods exposed to inappropriate environmental conditions, which is liable to the relevant responsible person. Mostly, indicators are used in the transportation or storage of goods. With different degrees of impact resistance for each package, you should select different models by different goods. There are 5 common product models: 100G, 75G, 50G, 37G, 25G, in order from least sensitive to most sensitive. In general, the colors of commercially available shock indicators follow the industry’s specifications. They are all eye-catching colors in order to attract the attention of couriers and handlers.

How to choose a suitable Shock Indicator Sticker?

Method 1 - The Fastest but Least Accurate

Calculate the volume (m3) and weight (kg) of your package and correspond with the right one. The Bigger & Heavier the goods are, the More Sensitive Stickers are Used. — 25G / 37G / 50G The Smaller & Lighter the goods are, the Less Sensitive Stickers are Used. — 50G / 75G / 100G

Method 2- Faster and More Accurate

This method is suitable for the products or packages which have tested by dropping in a lab. You can select the label closest to the product package dropping test result, based on the safety drop height. For example, the safety drop height is 70cm, then you can use shock indicator sticker 50G.

Method 3 - The Most Accurate

Apply all types of shock indicator stickers on the product or the package and do a drop test. You will have test data to analyze, and then find the most suitable label under your needs.